Managing a truck fleet means juggling dozens of moving parts and expenses. Between purchasing trucks, fuel, and repairs while remaining regulation-compliant, it doesn’t take long for costs to add up.

Running a fleet doesn’t have to feel like throwing money away. With the right strategy, you can stretch your dollar while keeping trucks moving safely and efficiently. Use these tips to create a cost-effective truck fleet management strategy.

1. Assess Your Current Fleet

Before making any significant changes, you must examine your existing setup. A thorough assessment shows you where you’re spending wisely and where equipment might be draining your budget.

Why Fleet Audits Matter

Performing your own audits is critical for protecting your fleet. In 2024, 93.6% of FMCSA safety investigations resulted in at least one violation. Evaluating your fleet for safety and cost concerns helps reduce violations and prevent future fines.

An audit is a deep dive into how your fleet is actually performing. Without knowing the details of fleet performance, it’s impossible to make cost-effective decisions. Some trucks might cost more in repair than they’re worth. Others could be underused but still have insurance and registration fees. A clear fleet baseline helps you make the best decisions for your fleet’s future.

Fleet Metrics to Review

Whether you have one truck or a full fleet, break down these metrics:

- Truck age: Age can influence performance. Older trucks often have more miles, increased repair visits, and reduced fuel efficiency. Look at mileage, model year, and major repair history. Sometimes an older truck with a clean history is worth keeping, but others might cost you more in downtime.

- Use rates: How often are you using each truck? Are some sitting idle while others work nonstop? Overuse accelerates wear and shortens truck life. You need to balance mileage across the fleet so all equipment delivers returns and lasts as long as possible.

- Maintenance history: A truck that spends more time in the shop than on the road is a financial drain. Calculate annual maintenance costs for each unit, including scheduled services and unexpected repairs. If a truck consistently costs more than it pulls in, it’s not a cost-effective investment.

- Fuel economy: Fuel costs are a constant fleet expense. Compare actual miles per gallon (MPG) against manufacturer standards to see how each truck performs. If they’re falling short, it could be a repairable issue or driver conduct, or it could be time to retire that truck.

Once you have this data, patterns will emerge. Maybe a few trucks are driving up your maintenance costs, or poor fuel use and planning are affecting MPG. When you understand your fleet metrics, you can make smarter decisions about retiring older units or investing in upgrades, which reduces truck fleet costs.

2. Schedule Preventive Maintenance

Preventive maintenance is at the heart of a budget-friendly fleet. It might seem counterintuitive at first, but spending regularly on maintenance will actually save you money in the long term. When repairs catch you off guard, you have to react to them. Fleet budgets might not have room for a sudden truck replacement or an extensive repair. Servicing trucks at structured intervals makes you proactive — care for your trucks regularly, instead of waiting for something to fail.

Invest in preventive maintenance with:

- Routine inspections: Regular inspections catch small issues early. Fleets can correct uneven tire wear or brake problems before they build into expensive major repairs.

- Scheduled services: Follow manufacturer recommendations for service schedules to keep trucks working at peak efficiency. Oil, filter, and fluid checks and changes reduce engine wear for a longer-lasting truck.

- Digital logs: Stay organized with digital maintenance logs. You can easily track and schedule maintenance or add vehicle notes so you never miss a critical service.

Skipping maintenance occasionally might seem like it’s reducing costs, but it’s just kicking the expenses down the road. Unplanned breakdowns come with bigger repair bills and downtime for trucks you need. Preventive maintenance reduces downtime, extends truck life, and protects drivers on the road.

Plan for Life Cycle Replacement

Even with the best preventive maintenance, every truck has a retirement date. Maintaining your vehicle until the day it breaks down completely leaves you scrambling for a replacement. Fleet managers can use life cycle replacement plans to make truck replacement more budget-friendly.

Life cycle replacement plans set guidelines for when to retire and replace trucks based on mileage, repair history, or operating hours. The goal is to replace a vehicle while it still holds value and before repair costs become a budget strain. With life cycle planning, you get:

- Reduced downtime: Fewer unexpected failures mean you stay productive more consistently.

- Improved safety: Newer trucks keep drivers safer and prevent them from dealing with breakdowns on the job.

- Higher resale value: Trucks replaced on schedule often still have good resale or trade-in value. Broken-down vehicles can’t command the same prices.

- Predictable budgeting: Replacement cycles let fleet managers plan for expenses like truck replacements, instead of shuffling finances around for a surprise purchase.

Each fleet will have a different replacement cycle depending on workload and truck use. What matters most is consistency. Fleet managers need to monitor performance data and set replacement dates so everything stays moving and cost-effective.

3. Optimize Routes and Fuel Efficiency

Fuel is one of the main costs of operating a fleet. Even small improvements in route planning or driving efficiency can yield noticeable cost savings.

Route Optimization

Every extra mile costs money. Route-planning software and GPS systems help minimize deadhead miles, reduce time in traffic, and limit idling. Use these tools to avoid peak travel windows or stagger departure times for more efficient driving. When trucks are moving, instead of being stuck in traffic or idling, fuel costs go down. Every penny saved can add up to thousands with route optimization.

Driver Habits

A truck’s performance is only as good as its driver. Aggressive acceleration, frequent idling, and poor shifting all eat into fuel efficiency. Your drivers need training on how to ease into speed and limit idling. Effective training and driver monitoring can lead to a 10% increase in fuel efficiency. With the right routing and driving habits, you can protect your equipment from strain and reduce fuel bills.

4. Leverage Technology for Fleet Management

Fleet management has moved into the future. Logbooks and spreadsheets are things of the past, slowing you down and making it harder to optimize your budgeting. Fleet managers can use modern technology to monitor trucks in real time, predicting problems and saving money. Fleets need:

- Telematics systems: These give you a live look at driver behavior, fuel consumption, fault codes, and idle time. Managers can use data to identify issues before they cause downtime and repairs.

- Predictive analytics: Predictive tools use truck patterns to anticipate potential breakdowns. Use analytics to schedule maintenance proactively, minimizing repair costs.

- Fleet management software: Use management software to pull everything together in one dashboard. This makes it easier to compare costs across trucks, keep up with maintenance schedules, and track long-term performance trends.

Software and telematics have upfront costs, but the payoff is significant. Better access to fleet data simplifies management and lets you pinpoint cost-cutting and improvement areas. You can stay ahead of breakdowns instead of reacting to them.

5. Choose Used Trucks Over New Trucks

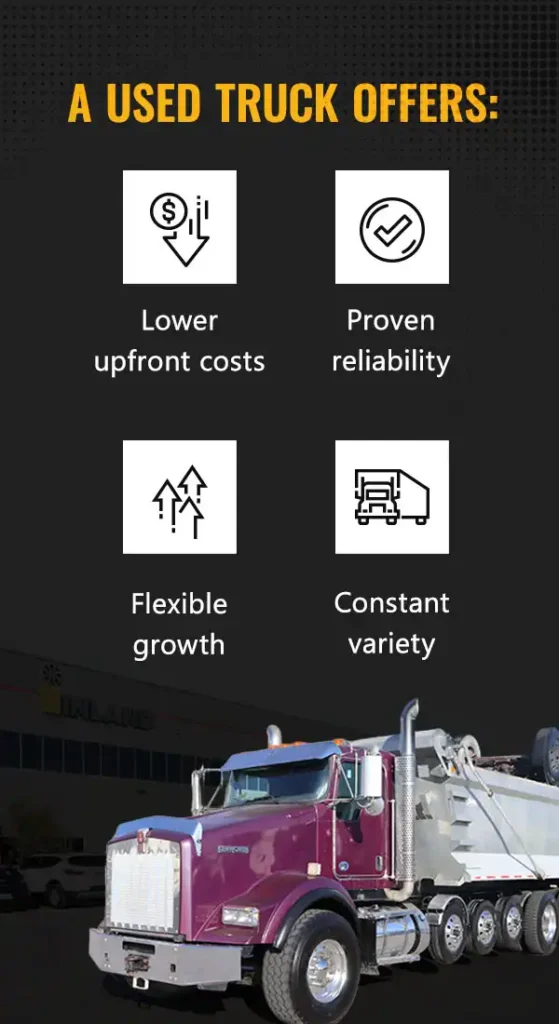

Buying a new truck from a reputable brand gets you top-of-the-line quality and performance, but budget-friendly fleets need budget-friendly solutions. Well-maintained used trucks can help you hit your productivity goals while minimizing expenses. A used truck offers:

- Lower upfront costs: New trucks lose a significant chunk of their value the moment they hit the road. Used models offer an affordable commercial truck solution and let fleet managers skip early depreciation without sacrificing quality. You avoid spending big on new equipment while maintaining the quality needed for trucking.

- Proven reliability: Trucks with documented service histories have already proven themselves on the job. Purchasing a used truck through a reputable dealer means you can be confident in the vehicle’s performance.

- Flexible growth: Buying used makes it easier to expand your fleet. You can buy more used trucks for the price of one new vehicle, growing your capabilities and keeping cash flow open.

- Constant variety: There are always new types of trucks moving through used dealers. Instead of being locked into that year’s trends, you can choose from various models to fit your business needs.

Track Total Cost of Ownership

Whether you’re buying used or new, or leasing, you need to think beyond the purchase price. A truck’s total cost of ownership (TCO) shows you exactly how much value you’re getting and what the cost will be. TCO includes:

- Purchase or lease price

- Fuel consumption over the truck’s life

- Maintenance and repair costs

- Depreciation

- Resale or trade-in value

Two trucks with a similar sticker price can have dramatically different long-term costs. One truck might cost a little more, but it delivers better fuel efficiency and stronger resale value. It could be more cost-effective in the long term than the slightly cheaper option.

By tracking TCO across your fleet, you’ll see which trucks deliver the best return and which are draining your budget. This will make future purchases easier since you’ll know which brands and models work best for your goals.

6. Consider Leasing vs. Buying Vehicles

Even if you’re looking to expand with used trucks, will you lease or buy them? Ownership has its advantages, but leasing is a flexible alternative, especially if your budget is tight.

Pros of Leasing

Leasing can be an excellent way to grow your fleet without taking on ownership responsibilities. It’s different from truck rentals, which are short-term agreements that fleet managers use to handle seasonal spikes. Leasing is a long-term agreement where you get to use a truck for years without the upfront payment needed for owning. Leasing offers:

- Lower upfront costs: Leasing reduces the strain on your cash flow. Instead of financing or paying for a truck up front, you lease it and make regular, on-time payments.

- Predictable payments: A set lease payment gives you predictable costs every month. This makes it easier to budget your expenses and prepare for the future.

- Access to newer technology: Leasing cycles let fleet managers upgrade more frequently, keeping drivers in newer, more fuel-efficient models.

Pros of Buying

Buying a truck gives you complete control over it. While it costs more upfront, you get to keep the vehicle and don’t have to worry about driving someone else’s truck. Buying offers:

- Ownership: Once the vehicle is paid off, it’s yours. After that, it’s all maintenance and insurance. You don’t continue to pay just to be able to use the vehicle.

- More freedom: Owned trucks can be outfitted with specialized equipment. Leases and rentals often have restrictions on what you can do to the vehicle.

- Long-term savings: Buying might be the better option if you plan to use your trucks for longer than a standard leasing period. You’ll save the most money over time by keeping your fleet in good condition.

7. Invest in Driver Training and Safety Programs

Drivers interact with trucks the most. They directly influence fuel costs, operating expenses, and profits. Focus on educating and rewarding drivers for budget-friendly, safe behavior.

Training programs help drivers know exactly what you expect of them. Ensure they understand proper load handling, defensive driving, and fuel-efficient habits. The more smoothly they drive, the better their fuel efficiency and route times. Defensive driving keeps them out of accidents, avoiding repair and liability bills. Invest in ongoing refresher programs and performance evaluations to motivate drivers and keep driving consistent.

Safety initiatives are also important. Distracted driving is a hazard on the road. You can use safety training or monitoring tools to keep drivers safer on the road. Fewer accidents mean lower insurance premiums and increased uptime.

8. Regularly Review and Adjust Your Budget

Building a budget truck fleet isn’t a one-time task. Costs change constantly. Fuel prices shift, trucks need maintenance, and you must be on top of it all. Review and adjust your budget for maximum savings.

How Reviews Help

Looking at your budget regularly — whether quarterly or semi-annually — helps you avoid rising costs and catch problem areas early. Maybe fuel expenses are higher than expected, or one truck’s repair needs differ from the rest of the fleet. Spotting these patterns helps you adjust before the budget spins out of control. Focus on:

- Scalability: If you’re scaling up, ensure the budget accounts for additional maintenance, trucks, and drivers.

- Flexibility: Build in buffer room for changes in costs of fuel, insurance, repairs, and potential accidents.

- Benchmarking: Use industry standards to compare your costs against the competition. Are you overspending where most companies aren’t?

Keep Your Fleet Cost-Effective with Inland

A budget-friendly fleet is your ticket to greater profits. But you need smart planning, the right equipment, and reliable support to make it happen. At Inland, we’ve been helping fleet managers make cost-effective decisions for over 70 years. We offer full maintenance support and top-quality trucks and parts for your fleet. If you’re in Southern California, Arizona, or New Mexico, visit us and explore the World’s Best® lineup of Kenworth trucks.